Carbon Capture, Utilization and Storage, or CCUS, is a process that will allow Louisiana’s industries that emit carbon dioxide (CO2) to both maintain their business plans and reduce CO2 emissions. First, it uses special equipment to remove the CO2 from their facilities’ exhaust before it reaches the air. Once captured, the CO2 can either be provided to companies for other uses or transported by pipeline to underground geologic formations certified for safe and permanent storage.

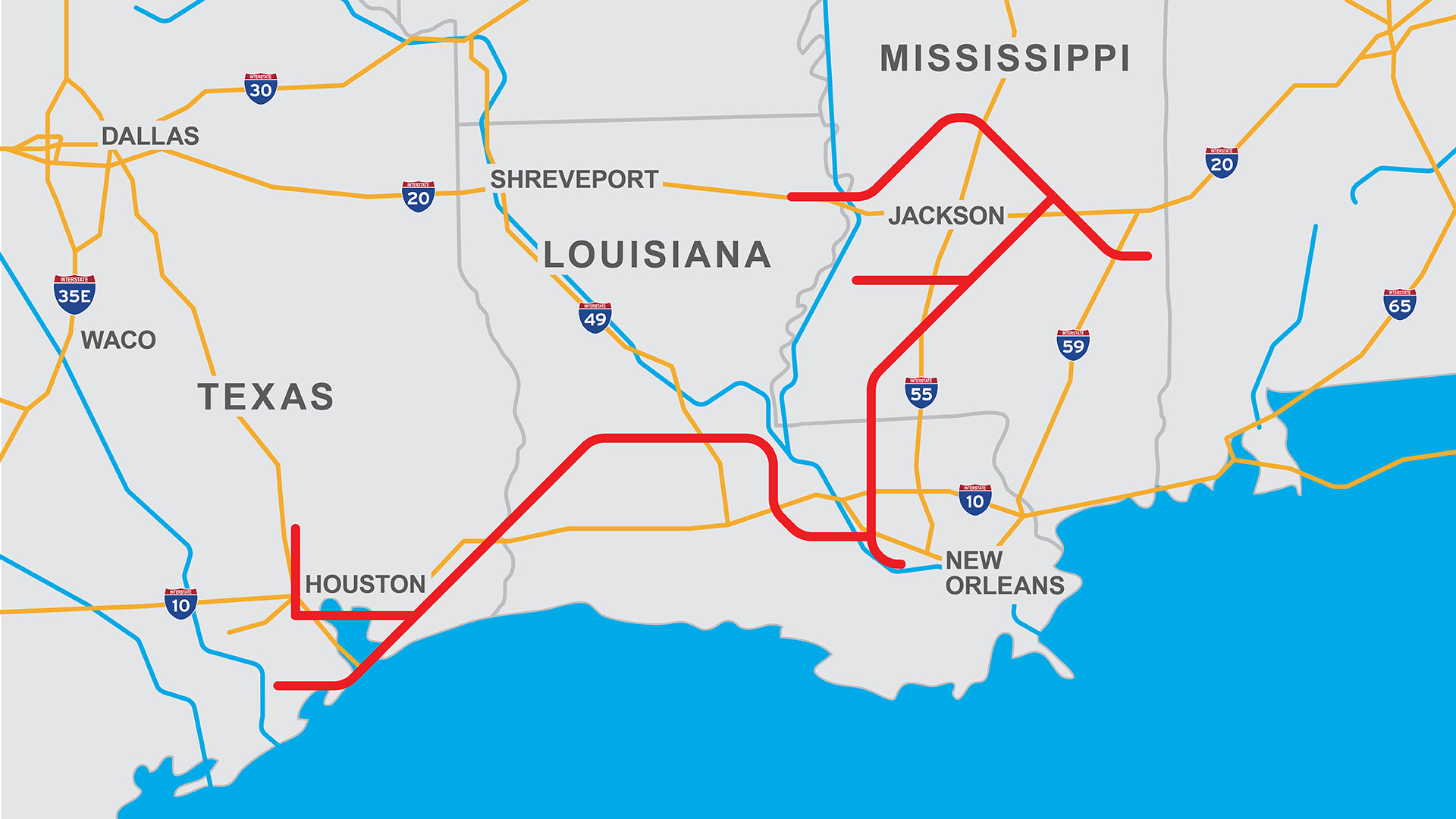

Pipelines have been safely transporting CO2 for more than 50 years. An expanded CO2 pipeline network can create new well-paying construction jobs and help sustain Louisiana’s industrial jobs.

ExxonMobil Pipeline Company currently operates the largest network of CO2 pipelines in Louisiana. It is supporting ExxonMobil Low Carbon Solutions’ CCUS projects by helping build new pipeline segments connecting existing CO2 pipelines to additional storage sites.

Safety is Priority Number One for ExxonMobil Pipeline Company. We will meet or exceed regulatory requirements and industry best practices during construction. We also are committed to being good neighbors in the communities where we operate and responsible stewards of the environment through which our pipelines travel.

Learn More

ExxonMobil Pipeline Gulf Coast CO2 Network